measure

to move

Sphere and Features

location-independent, fully self-sustained,

minimalized microsensors

for an accelerated and

more effective process development

measure

to move

- Efficiency gains in process preparation through wireless systems

- Easy parallelization of measurements in multiple vessels by a gateway

- Redundant measurements increase process safety

- Minimal process interference leads to reproducible results

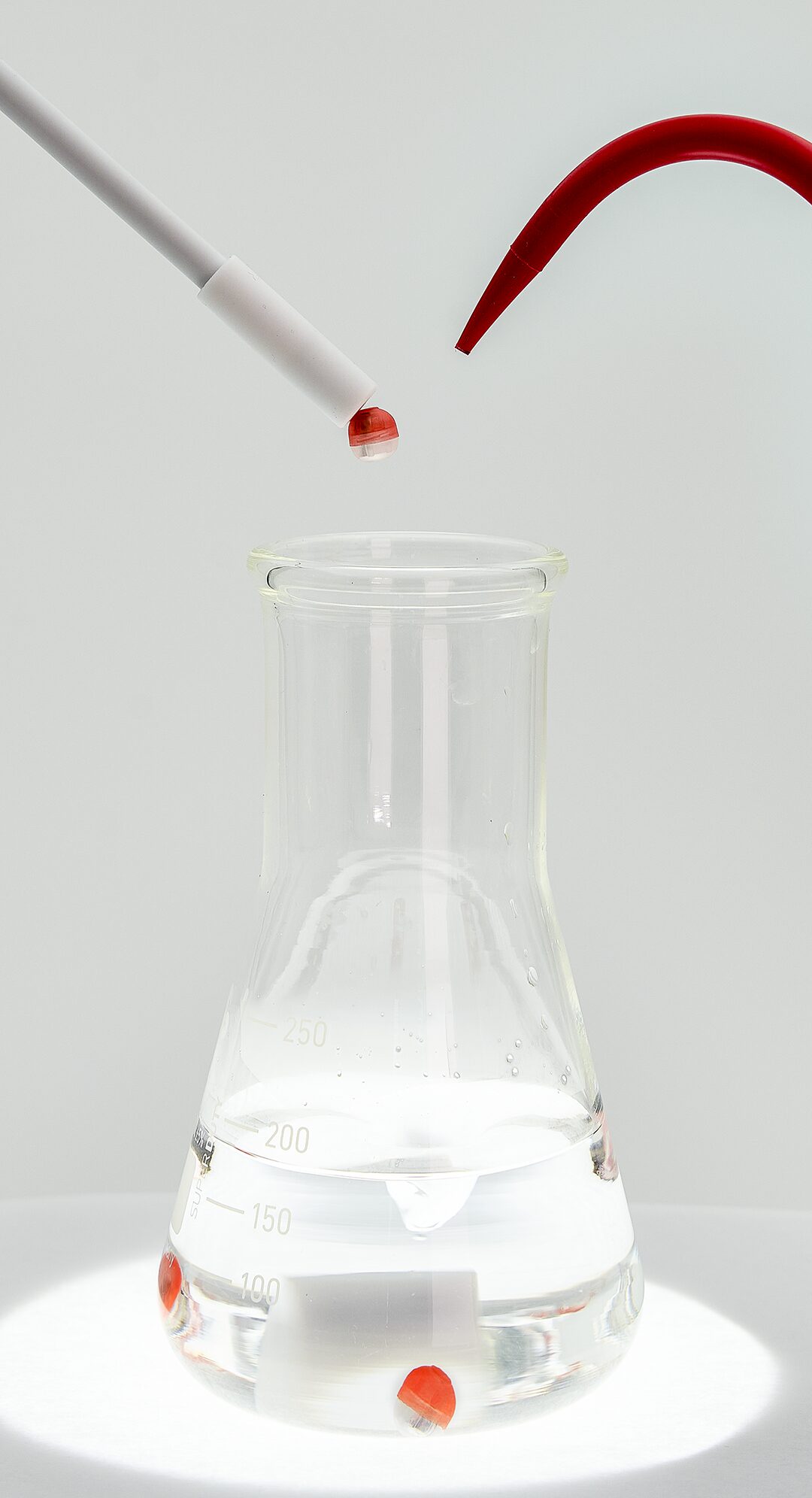

- Measurement independent from vessel geometry and volume

- Accelerates research and development processes; whether in a shaking flask with a few milliliters or in a 200-liter wave bag reactor

wireless recharging

replenish for multiple use

bioinert

generate data without interfering with your system

online data

wireless and online transmission of process data

flow following

evenly distributes in your reaction system

highly parallelised

up to 24 Sens-o-Spheres per measurement system

compact design

temperature acquisition on the size of a cherry pit

Applications

Enables measurement

in moving systemsOnline data in the blink

of an eye through wireless

communication Validate your systems

of daily use

Universal

sensing system

for all reactor types

and sizes

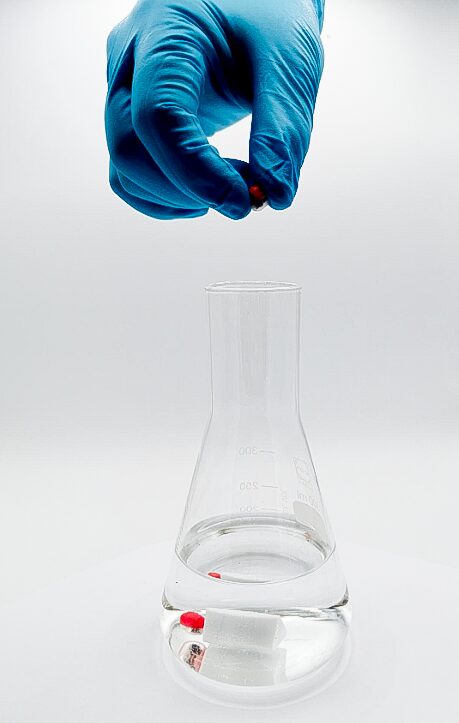

Spheres

Make your measurement versatile

4 x Sens-o-Spheres for your installation-free measurements. Upgrade to the number of sensors suitable for your application.

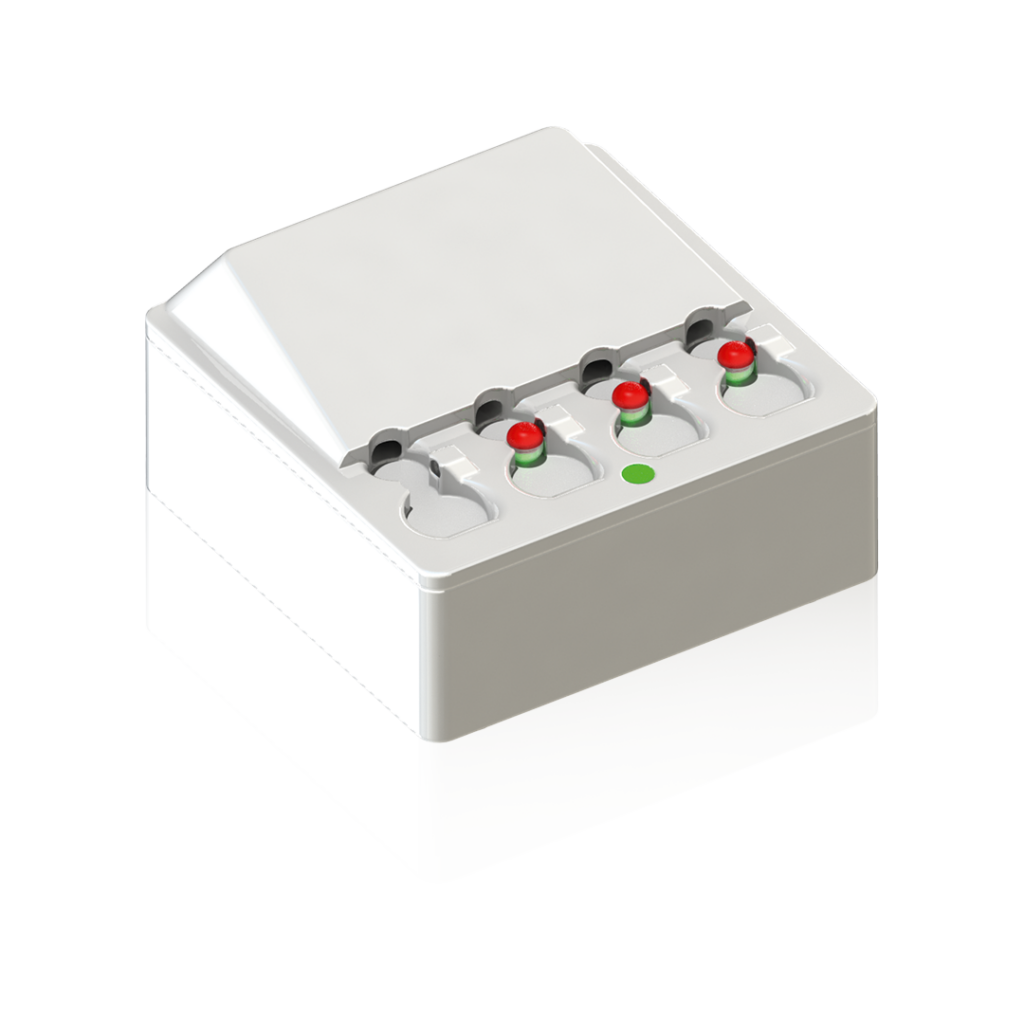

Gateway

Control your sensors everywhere

Transceiver with user interface. Starting point for your measurement with Sens-o-Spheres. Serves up to 24 sensors simultaneously.

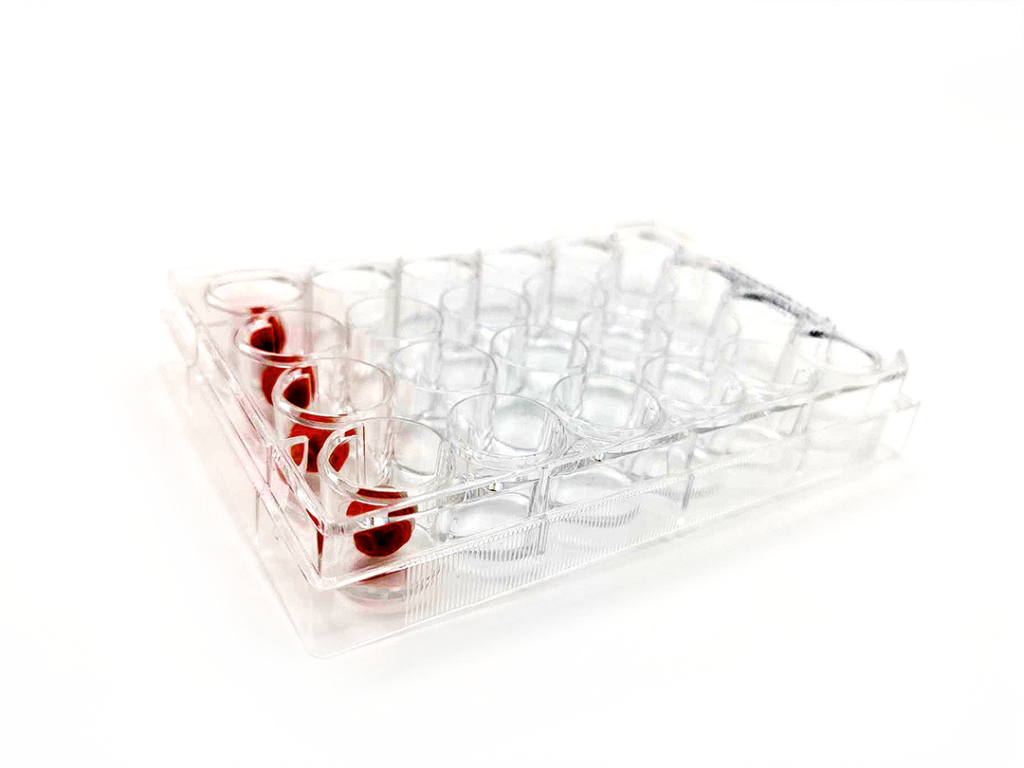

Charger

Keep your system recharged

4 wells to recharge your Sens-o-Spheres for multiple uses. Wireless charging enables a clean design.

Technical Data

| Runtime | At least 48 h |

| Intervals | 10 s |

| Life cycles | Up to 10 times |

| Distance to Gateway | Up to 5 m in a laboratory environment |

| Reactor requirements | Radio transmissible window Reactors up to pilot scale |

| Sanitizable |  |

| Calibratable |  |

| Measurement range | 10 °C to 60 °C |

| Accuracy | ± 0.5 °C* at 35 °C |

| Resolution | 0.0625 °C |

| Response Time (τ63) | 30 s |